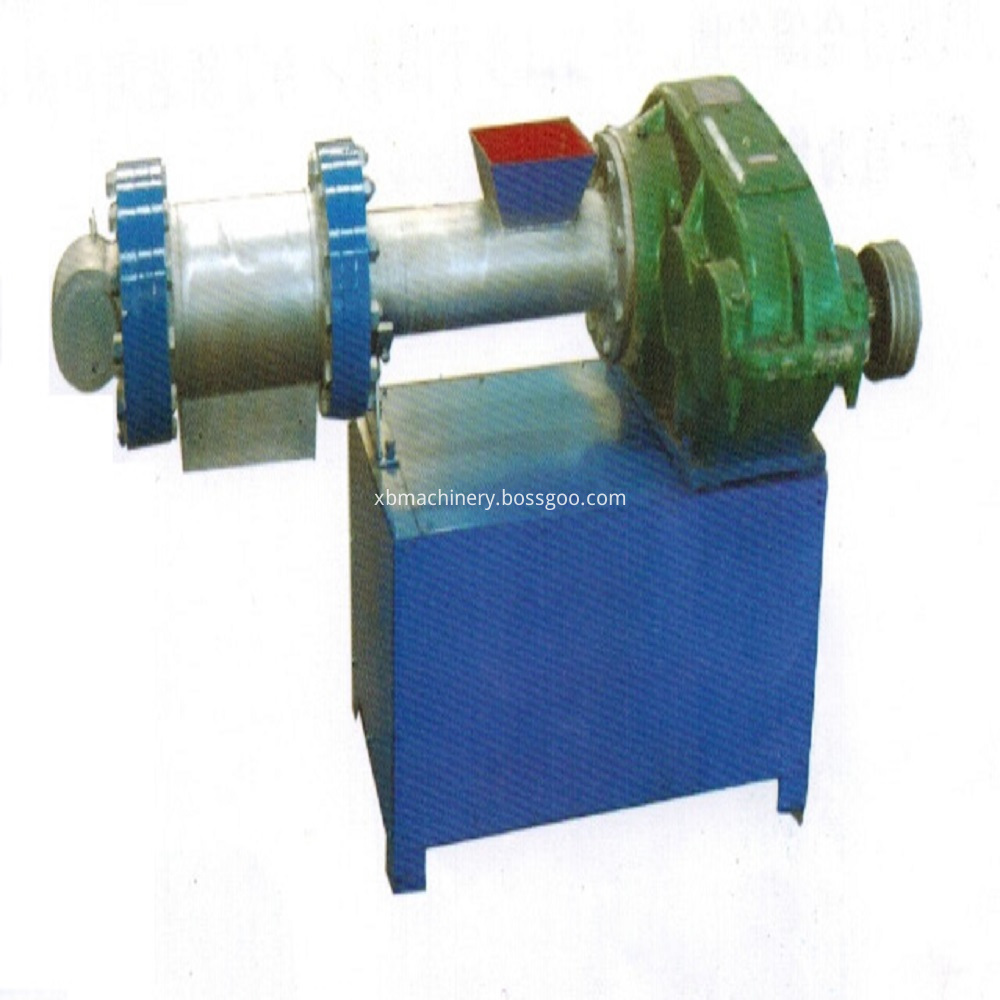

Extruded and Foamed waste Polystyrene machine

Basic Info

Model No.: XB-V5/39

Product Description

1. Parallel co-rotating twin-screw extruder barrel, the screw is designed and manufactured by building block principle. According to the processing material system and process formula, the length-to-diameter cylinder structure, screw arrangement, membrane network structure, exhaust quantity position, feeding mode, electrical control mode, etc. can be optimized and rationally configured. Achieve versatility and versatility to accommodate advanced materials.

2. New deceleration distribution transmission system, high-rug design, high-precision gear processing, main bearings adopt imported parts, reasonable oil-immersed combined with forced lubrication device, and interlocking protection device to ensure reliable and stable operation of the main engine.

3. Make full use of the limited space to design the latest progressive spline form structure, mandrel. Guarantee maximum load carrying capacity and achieve high regulation transmission.

4. Using a computer

Foam granulator features:

1. The main and auxiliary screw barrels are made of high-strength carbon structural steel.

2. The foam pellet machine adopts cone-shaped screw barrel, which has fast feeding speed and high output.

3, the use of main and auxiliary machine supporting production, heating temperature is stable, effectively improve the molecular structure of the material, enhance air permeability, particle quality has improved significantly!

4. The foam particle unit is mainly composed of a crusher, a host machine, and an automatic traction granulator, and the host adopts an automatic network changing device.

Foam granulator is a typical granulator product that is professionally built. Its superior performance, reasonable structure, and durable materials. This type of pelletizer has better sealing and less leakage. Easy to adjust knife pitch. The rotary cutter is a hard alloy hob, which has extremely high wear resistance. The whole gearless design is driven by a belt, which effectively reduces the machine operating noise. The independent electrical box of the pelletizer is convenient, safe and beautiful.

company Describes

Shandong Qufu Xingbang Heavy Industry Equipment Co., Ltd. will build a science and technology leading enterprise integrating R&D, manufacturing and installation, and international trade. The main products developed and manufactured include building materials equipment: automatic glass magnesium fireproof board production line, large-scale multi-functional wall board exterior wall insulation board production line, environmental fireproof door core board production line, new energy straw board making machine, fully automatic cutting saw; woodworking machinery : Automatic veneer machine, sticker machine, automatic curing machine, UV light curing machine, hot pressing veneer machine, vacuum machine, cold press machine, universal coating machine and other products, all of which have passed the relevant national departments The technical appraisal and recognition has enjoyed a good reputation in the market and has been well received by customers. The company's products are sold to all parts of the country and some surrounding countries and have achieved high economic and social benefits.

Building Material Making Machinery

Glass Magnesium Fire Prevention Board Plate Automatic Production Line

Glass Magnesium Fire Board Decorating Plate Production Line

Plastic Extrusion And Recovery Equipment

Plastic Extruder Machine

Plastic Pelletizing Recycling Machine

Sheet Plate Board Extrusion Line

Plastic Washing Recycling Machine

Product Categories : Plastic Extrusion And Recovery Equipment > Plastic Extruder Machine