Click on the follow link to find out more information: https://www.plasticmetalmachining.com/cnc-milling/

Company Info

- Company Name: Ningbo Rongna Technology Co.,Ltd

- Representative: Jewel Luo

- Product/Service: cnc machining service , injection molding service , 3d printing service , cnc turning , cnc milling , rapid prototype

- Capital (Million US $): 10,00000RMB

- Year Established: 2020

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 91% - 100%

- Total Annual Purchase Volume (Million US $): US$2.5 Million - US$5 Million

- No. of Production Lines: 10

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: No.69 ZiLin Road,YuYao ,ZheJiang Province

- Contact Person: Ms. Jewel

- Tel: +86-0574-62520922

Premium Related Products

Other Products

Hot Products

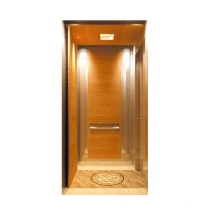

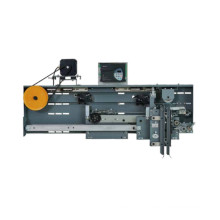

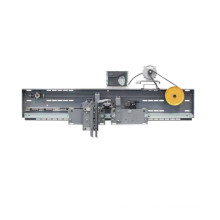

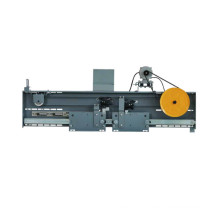

200kg Single Speed Geared FREIGHT LIFT partsPASSENGER ElevatorMCG250 gearless traction machineMCG350 gearless traction machineMCG300 gearless traction machineMCG210 gearless traction machineMCG200 gearless traction machineMCG130 gearless traction machineMCG150 gearless traction machineMCG100 gearless traction machineMONA320C gearless traction machineMONA320B gearless traction machineMONA320A gearless traction machineMONA200C gearless traction machineMONA200B gearless traction machineMONA200A&A1 gearless traction machine